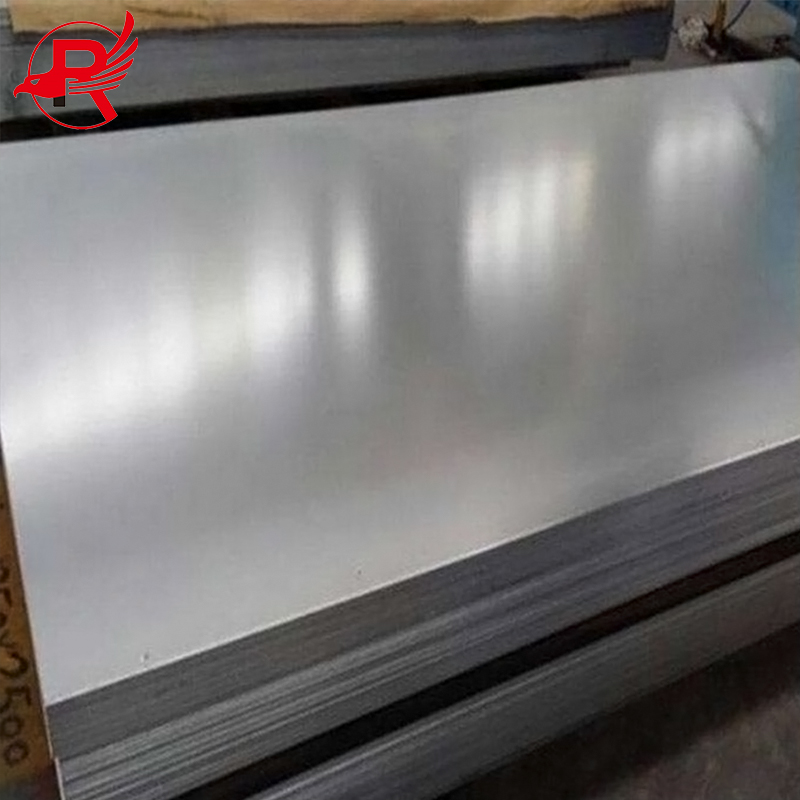

Takardar Karfe Mai Galvanized SGCE 1mm 3mm 5mm 6mm Farantin Karfe Mai Inganci Mai Kyau

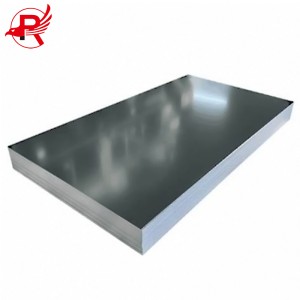

Takardun ƙarfe na GI zanen gado ne da aka yi da ƙarfe mai galvanized (GI). Takardun galvanization tsari ne na shafa ƙarfe ko ƙarfe da wani Layer na zinc don hana tsatsa. Ana amfani da zanen gado na GI sosai don rufin gida, shinge, da aikace-aikacen waje saboda dorewarsu da juriya ga tsatsa da tsatsa.

Ana auna kauri na zanen gado na GI ta hanyar ma'auni, tare da ƙaramin ma'auni yana nuna takardar kauri. Ma'aunin da aka fi amfani da su don zanen gado na GI yana tsakanin 18 zuwa 24. Faɗin zanen gado na GI yawanci yana tsakanin 600mm zuwa 1500mm.

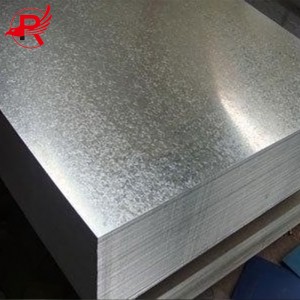

Farantin Karfe Mai GalvanizedAna samun su a nau'ikan shafi guda biyu: spangle na yau da kullun da sifili spangle. Takardun GI na spangle na yau da kullun suna da tsari mai kama da spangle a saman, wanda aka ƙirƙira yayin aikin galvanizing. Takardun GI na sifili spangle, a gefe guda, suna da santsi kuma ba su da wani tsari na spangle da ake iya gani.

Takardar Karfe da aka GalvanizedAna iya rarraba su bisa ga amfaninsu. Wasu daga cikin nau'ikan takardar GI da aka saba amfani da su sun haɗa da:

1. Takardun GI masu lankwasa - ana amfani da su don rufin gida, bangarorin bango, da kuma shinge.

2. Takardun GI marasa nauyi - ana amfani da su don aikace-aikacen cikin gida kamar bututun iska, allunan lantarki, da kayan daki.

3. Takardun Galvalume GI - haɗin zanen GI mai rufi da aluminum da zinc wanda ke ba da juriya ga tsatsa.

4. Takardun GI da aka riga aka fenti - Takardun GI da aka shafa da fenti, wanda aka saba amfani da shi don rufin gida da rufin gida.

Ana samun zanen gado na GI a matakai daban-daban dangane da ƙarfi da juriyarsu. Maki da aka fi amfani da su don zanen gado na GI sune SGCC, SGHC, da DX51D.

1. Juriyar tsatsa, iya fenti, iya tsari da kuma iya walda tabo.

2. Yana da amfani iri-iri, galibi ana amfani da shi ga sassan ƙananan kayan aikin gida waɗanda ke buƙatar kyakkyawan tsari, amma ya fi tsada fiye da SECC, don haka masana'antun da yawa suna canzawa zuwa SECC don rage farashi.

3. An raba shi da zinc: girman spangle da kauri na layin zinc na iya nuna ingancin galvanizing, ƙarami da kauri sun fi kyau. Masu kera kuma za su iya ƙara maganin hana yatsa. Bugu da ƙari, ana iya bambanta shi ta hanyar shafa shi, kamar Z12, wanda ke nufin cewa jimlar adadin shafa a ɓangarorin biyu shine 120g/mm.

Takardun GI suna da nau'ikan aikace-aikace iri-iri a masana'antu da sassa daban-daban. Wasu daga cikin aikace-aikacen da aka saba amfani da su na takardar GI sune:

1. Rufi da Rufi:Farantin Karfe Mai ZafiAna amfani da su sosai a gine-ginen gidaje, kasuwanci, da masana'antu, saboda dorewarsu, juriyarsu ga tsatsa, da kuma ƙarfinsu.

2. Katanga: Ana amfani da zanen gado na GI don ƙirƙirar shinge da shinge saboda ƙarfinsu da kuma juriyarsu ga tsatsa. Haka kuma ana amfani da su azaman ganuwar iyaka don dalilai na tsaro.

3. Motoci: Ana amfani da zanen gado na GI don ƙera sassan motoci kamar su bangarorin jiki, rufin gida, da kuma chassis saboda ƙarfi da dorewarsu.

4. HVAC: Ana amfani da zanen gado na GI a masana'antar dumama, iska, da kwandishan (HVAC) don bututun iska, na'urorin sanyaya iska, da tsarin iska.

5. Ƙirƙira: Ana amfani da zanen gado na GI a masana'antar ƙera kayayyaki daban-daban kamar kabad, shiryayye, kayan daki, da sauran kayayyakin ƙarfe.

6. Lantarki: Ana amfani da zanen gado na GI don ƙera bangarorin kewaye na lantarki saboda dorewarsu, ƙarfinsu, da juriyarsu ga tsatsa.

7. Noma: Ana amfani da zanen gado na GI a noma don gina rumfunan kaji, wuraren ajiye kaji, da wuraren ajiya.

Gabaɗaya, takaddun GI suna ba da mafita mai aminci da araha ga aikace-aikace da yawa kuma ana amfani da su sosai a masana'antu da sassa da yawa.

| Tsarin Fasaha | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Karfe Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340, SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); ko na Abokin Ciniki Bukatar |

| Kauri | buƙatar abokin ciniki |

| Faɗi | bisa ga buƙatar abokin ciniki |

| Nau'in Shafi | Karfe Mai Zafi (HDGI) |

| Shafi na Zinc | 30-275g/m2 |

| Maganin Fuskar | Passivation(C), Man shafawa(O), Hatimin lacquer(L), Phosphating(P), Ba a yi wa magani ba(U) |

| Tsarin Fuskar | Rufin spangle na yau da kullun (NS), murfin spangle da aka rage girmansa (MS), ba shi da spangle (FS) |

| Inganci | An amince da SGS, ISO |

| ID | 508mm/610mm |

| Nauyin Nauyin Nauyi | Tan metric 3-20 a kowace na'ura |

| Kunshin | Takardar da ke hana ruwa ta ƙunshi marufi na ciki, an yi mata fenti da ƙarfe mai rufi ko kuma an yi mata fenti da ƙarfe mai rufi, an yi mata fenti da ƙarfe mai kauri, sannan an naɗe ta da ƙarfe mai kauri. bel ɗin ƙarfe bakwai. ko kuma bisa ga buƙatun abokin ciniki |

| Kasuwar fitarwa | Turai, Afirka, Asiya ta Tsakiya, Kudu maso Gabashin Asiya, Gabas ta Tsakiya, Kudancin Amurka, Arewacin Amurka, da sauransu |

| Teburin Kwatanta Kauri Mai Ma'auni | ||||

| Ma'auni | Mai laushi | Aluminum | An yi galvanized | Bakin karfe |

| Ma'auni na 3 | 6.08mm | 5.83mm | 6.35mm | |

| Ma'auni 4 | 5.7mm | 5.19mm | 5.95mm | |

| Ma'auni 5 | 5.32mm | 4.62mm | 5.55mm | |

| Ma'auni na 6 | 4.94mm | 4.11mm | 5.16mm | |

| Ma'auni 7 | 4.56mm | 3.67mm | 4.76mm | |

| Ma'auni 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Ma'auni 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Ma'auni 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Ma'auni 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Ma'auni 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Ma'auni 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Ma'auni 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Ma'auni 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Ma'auni 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Ma'auni 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Ma'auni 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Ma'auni 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Ma'auni 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Ma'auni na 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Ma'auni 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Ma'auni 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Ma'auni 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Ma'auni 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Ma'auni 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Ma'auni 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Ma'auni 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Ma'auni na 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Ma'auni 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Ma'auni 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Ma'auni 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Ma'auni 33 | 0.22mm | 0.18mm | 0.24mm | |

| Ma'auni 34 | 0.20mm | 0.16mm | 0.22mm | |

1. Nawa ne farashin ku?

Farashinmu na iya canzawa dangane da wadata da sauran abubuwan kasuwa. Za mu aiko muku da sabon jerin farashi bayan tuntuɓar kamfanin ku.

mu don ƙarin bayani.

2. Shin kuna da mafi ƙarancin adadin oda?

Eh, muna buƙatar duk oda na ƙasashen duniya su kasance suna da mafi ƙarancin adadin oda. Idan kuna neman sake siyarwa amma a ƙananan adadi, muna ba da shawarar ku duba gidan yanar gizon mu.

3. Za ku iya samar da takaddun da suka dace?

Eh, za mu iya samar da mafi yawan takardu, gami da Takaddun Shaida na Bincike / Yarjejeniyar; Inshora; Asali, da sauran takaddun fitarwa inda ake buƙata.

4. Menene matsakaicin lokacin jagoranci?

Ga samfura, lokacin jagora yana kimanin kwanaki 7. Don samar da kayayyaki da yawa, lokacin jagora shine kwanaki 5-20 bayan karɓar kuɗin ajiya. Lokacin jagora yana aiki lokacin da

(1) mun karɓi kuɗin ajiyar ku, kuma (2) muna da amincewar ku ta ƙarshe don samfuran ku. Idan lokacin da muke bayarwa bai yi aiki da wa'adin lokacin da aka ƙayyade ba, da fatan za a sake duba buƙatun ku tare da siyarwar ku. A duk lokuta za mu yi ƙoƙarin biyan buƙatun ku. A mafi yawan lokuta za mu iya yin hakan.

5. Waɗanne irin hanyoyin biyan kuɗi kuke karɓa?

Kashi 30% a gaba kafin T/T, kashi 70% za su kasance kafin jigilar kaya akan FOB; kashi 30% a gaba kafin T/T, kashi 70% idan aka kwatanta da kwafin BL basic akan CIF.