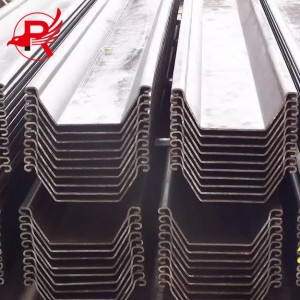

Tarin Karfe Mai Siffa Mai Zafi Mai Siffa U Mai Inganci Don Sayarwa

| Sunan Samfuri | takardar tari u type don kariyar kogi |

| Fasaha | birgima cikin sanyi/birgima da zafi |

| Daidaitacce | GB/JIS/DIN/ASTM/AISI/EN da sauransu. |

| Kayan Aiki | Q234B/Q345B |

| JIS A5523/ SYW295,JISA5528/SY295,SYW390,SY390 ect. | |

| Aikace-aikace | Cofferdam /Gudanar da ayyukan shawo kan ambaliyar ruwa a Kogi/ |

| Tsarin maganin ruwa shinge/Kariyar ambaliyar ruwa /Bangare/ | |

| Gaɓar kariya/Gidan gabar teku/Yanke rami da ramukan rami/ | |

| Ruwan fashewa/Bangon Gilashi/ Gangaren da aka gyara/Bangon da ya yi tsauri | |

| Tsawon | 6m, 9m, 12m, 15m ko kuma an keɓance shi |

| Matsakaicin mita 24 | |

| diamita | 406.4mm-2032.0mm |

| Kauri | 6-25mm |

| Samfuri | An biya an bayar |

| Lokacin gabatarwa | Kwanaki 7 zuwa 25 bayan karɓar 30% na ajiya |

| Sharuɗɗan biyan kuɗi | 30% TT don ajiya, 70% ma'auni kafin jigilar kaya |

| shiryawa | Fitar da kayayyaki ta yau da kullun ko bisa ga buƙatar abokin ciniki |

| Kunshin | An haɗa |

| Girman | Buƙatar Abokin Ciniki |

Thetarin takardar ufa'idodi

Tarin takardar ƙarfe mai siffar U yana da fa'idodi masu zuwa:

Babban Ƙarfi:tarin takardar U typean yi shi ne da ƙarfe mai ƙarfi kuma yana da ikon ɗaukar nauyin manyan ayyukan injiniya.

Dorewa: Tarin takardar ƙarfe mai siffar U yana da kyakkyawan juriya ga tsatsa da kuma juriyar lalacewa, kuma yana iya jure wa amfani na dogon lokaci a ƙarƙashin yanayi daban-daban na muhalli.

Ingantaccen Gini:Tarin takardar uyana ɗaukar tsarin haɗakarwa, wanda zai iya kammala gini cikin ɗan gajeren lokaci da kuma inganta ingancin gini.

sassauci: Girman da tsawontarin takardar U typeza a iya daidaita shi bisa ga buƙatun takamaiman ayyuka, tare da ƙarfin daidaitawa da sassauci.

Kare Muhalli: Ana iya sake yin amfani da tarin takardar ƙarfe mai siffar U, rage tasirin muhalli, tare da kyakkyawan aikin muhalli.

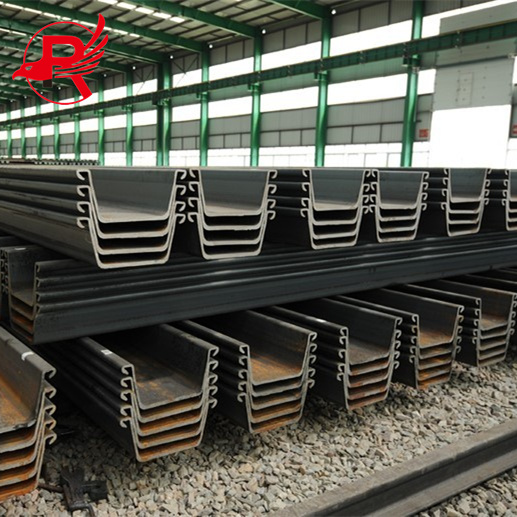

Jerin aikace-aikacenu nau'in takardar ƙarfeyana da faɗi sosai, gami da waɗannan fannoni:

Injiniyan Gidaje: Ya dace da tallafin tushe, riƙe bango, da daidaita gangara, don tabbatar da aminci da dorewar gine-gine.

Ayyukan Ruwa: Ya dace da tashoshin jiragen ruwa, gadoji, da kuma kariyar bakin teku, wanda ke ba da aiki mai ɗorewa a cikin mawuyacin yanayi na ruwa.

Ajiye Ruwa: Yana ƙarfafa madatsun ruwa, magudanan ruwa, da ayyukan tsara koguna tare da tallafin gini mai dogaro.

Kayayyakin Layin Dogo: Yana tallafawa gaɓar ruwa, ramuka, da gadoji yadda ya kamata, yana haɗa ƙarfi tare da sauƙin shigarwa.

Ayyukan Haƙar Ma'adinai: Yana ƙarfafa tushe da gangara a wuraren haƙar ma'adinai da wuraren adana kayan aiki, yana tabbatar da aminci da dorewa.

Mai ɗorewa, mai sauƙin shigarwa, kuma mai sauƙin shigarwa — Tarin zanen ƙarfe mai siffar U sune zaɓin da aka amince da shi don ayyukan gini a sassa daban-daban.

Bayani:

1. Samfur kyauta, tabbacin inganci 100% bayan tallace-tallace, Goyi bayan kowace hanyar biyan kuɗi;

2. Duk wasu bayanai game da bututun ƙarfe mai zagaye suna samuwa bisa ga buƙatarku (OEM&ODM)! Farashin masana'anta za ku samu daga ROYAL GROUP.

Tsarin Masana'antar Takardar Karfe ta U-Type

| Mataki | Babban Bukatun | Manufa |

| Maganin Kayan Danye Kafin A Yi | Zaɓi ƙarfe mai ƙarfi, a yi yanka, sarrafa injina da kuma maganin zafi | A kafa harsashin ingancin samfur da ƙarfi |

| Ƙirƙirar Mold | Yi ƙirar sama, ƙirar ƙasa da ƙirar gefe bisa ga zane-zanen ƙira | Cika buƙatun ƙirƙirar nau'in U |

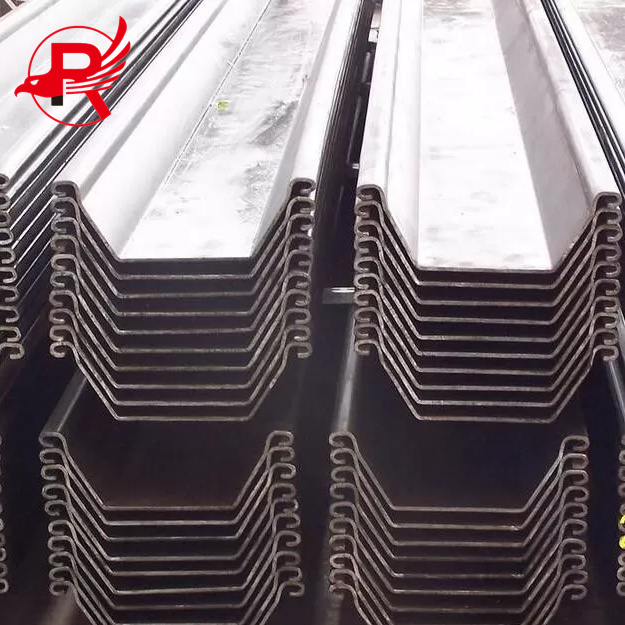

| Tsarin Lanƙwasawa Mai Sanyi | Sarrafa faranti na ƙarfe da aka riga aka yi musu magani ta hanyar injunan lanƙwasa sanyi | Samar da siffar U-type ta asali |

| Yankan da hakowa | Daidai tsari bisa ga ƙayyadaddun ƙira | Biyan buƙatun haɗawa da shigarwa a wurin |

| Samar da Haɗi | Haɗa cikin ganuwar da ke ci gaba | Daidaita da yanayin ginin wurin |

| Maganin Fuskar | Gudanar da hanyoyin feshi da galvanizing | Inganta juriyar tsatsa da kuma tsawaita rayuwar sabis |

| Marufi da Sufuri | Daidaita marufi na kayayyakin da aka gama | Jigilar kaya zuwa wurin ginin lafiya |

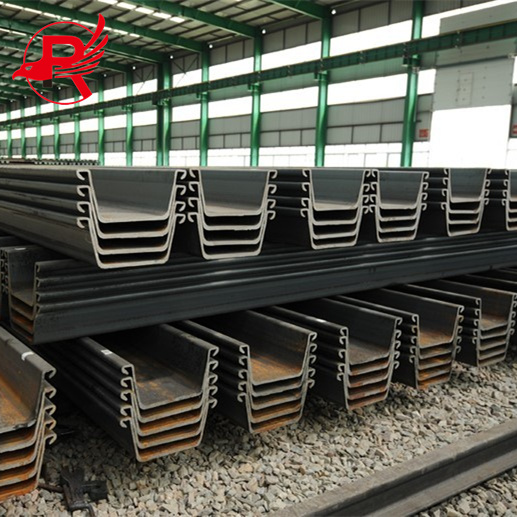

Marufi gabaɗaya tsirara yake, ɗaure waya ta ƙarfe, yana da ƙarfi sosai.

Idan kuna da buƙatu na musamman, zaku iya amfani da marufi mai hana tsatsa, kuma mafi kyau.

Sufuri:Isarwa ta Gaggawa (Samfurin Isarwa), Jirgin Sama, Jirgin Kasa, Jirgin Ruwa (FCL ko LCL ko Babban Jiki)

Abokin ciniki mai nishadantarwa

Muna karɓar wakilan China daga abokan ciniki a duk faɗin duniya don ziyartar kamfaninmu, kowane abokin ciniki yana cike da kwarin gwiwa da aminci ga kamfaninmu.

T: Shin masana'anta ne?

A: Eh, mu masana'anta ne. Muna da masana'antarmu da ke birnin Tianjin, China.

T: Zan iya samun odar gwaji kawai tan da yawa?

A: Tabbas. Za mu iya jigilar kayan a gare ku tare da sabis na LCL. (Ƙarancin nauyin kwantena)

T: Idan samfurin kyauta ne?

A: Samfura kyauta ne, amma mai siye yana biyan kuɗin jigilar kaya.

T: Shin kai mai samar da zinare ne kuma kana da tabbacin ciniki?

A: Muna da shekaru bakwai na mai samar da zinare kuma muna karɓar tabbacin ciniki.