API 5L Gr. B Carbon Layin Bututu Mara Sumul

| Maki | API 5L Grade B, X42, X52, X56, X60, X65, X70, X80 |

| Matakin Ƙayyadewa | PSL1, PSL2 |

| Nisan Diamita na Waje | 1/2” zuwa 2”, 3”, 4”, 6”, 8”, 10”, 12”, inci 16, inci 18, inci 20, inci 24 har zuwa inci 40. |

| Jadawalin Kauri | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, zuwa SCH 160 |

| Nau'ikan Masana'antu | Ba shi da sumul (An yi birgima da zafi da sanyi), An yi walda da ERW (an yi walda da juriyar wutar lantarki), SAW (An yi walda da baka mai zurfi) a cikin LSAW, DSAW, SSAW, HSAW |

| Nau'in Ƙarshe | Ƙarshen da aka yanke, Ƙarshen da aka yanke |

| Nisan Tsawon | SRL (Tsawon Bazuwar Guda ɗaya), DRL (Tsawon Bazuwar Guda Biyu), 20 FT (mita 6), 40 FT (mita 12) ko, an keɓance shi |

| Hulunan Kariya | filastik ko ƙarfe |

| Maganin Fuskar | Zane na Halitta, Mai Launi, Baƙi, FBE, 3PE (3LPE), 3PP, CWC (An Rufe Nauyin Siminti) CRA Mai Rufi ko Layi |

Bututun API 5L yana nufin bututun ƙarfe na carbon da ake amfani da shi a tsarin watsa mai da iskar gas. Haka kuma ana amfani da shi don jigilar wasu ruwaye kamar tururi, ruwa, da laka.

Tsarin API 5L ya ƙunshi nau'ikan ƙera da aka haɗa da walda da kuma waɗanda ba su da matsala.

Nau'ikan Welded: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

Nau'ikan bututun API 5L da aka ƙera kamar haka::

ERW: Walda mai jure wa wutar lantarki, wanda aka saba amfani da shi don diamita na bututu ƙasa da inci 24.

DSAW/SAW: Walda mai gefe biyu a ƙarƙashin ruwa/walda mai nutsewa a cikin ruwa, wata hanyar walda daban da ERW da ake amfani da ita don manyan bututu masu diamita.

LSAW: Walda mai tsawon tsayi a ƙarƙashin ruwa, wanda ake amfani da shi don diamita na bututu har zuwa inci 48. Hakanan an san shi da tsarin ƙera JCOE.

SSAW/HSAW: Walda mai kauri a ƙarƙashin ruwa/walda mai karkace a ƙarƙashin ruwa, wanda ake amfani da shi don diamita na bututu har zuwa inci 100.

Nau'ikan Bututu Mara Sumul: Bututu mai zafi mai birgima mara sumul

Ana amfani da bututun ƙarfe mara sulɓi ga ƙananan bututun diamita (yawanci ƙasa da inci 24).

(Bututun ƙarfe mara sumul ya fi bututun da aka haɗa da na'urar walda idan diamita bai wuce mm 150 ba (inci 6)).

Muna yin babban bututu mai kauri mara kauri. Ta hanyar amfani da tsari mai zafi, ana iya ƙera bututu mara kauri mai matsakaicin diamita na inci 20 (508 mm). Idan kuna buƙatar bututu mara kauri mai diamita fiye da inci 20, za mu iya ƙera bututu mara kauri ta hanyar tsari mai kauri mai diamita har zuwa inci 40 (1016 mm).

API 5L ya haɗa da maki kamar Grade B, X42, X46, X52, X56, X60, X65, X70 da X80.

Ana samun bututun ƙarfe na API 5L a cikin nau'ikan ƙarfe da yawa, ciki har da Grade B, X42, X46, X52, X56, X60, X65, X70 da X80. Yayin da ƙarfin ƙarfe ya yi yawa, haka ƙarfin sarrafa carbon ɗin yake ƙaruwa kuma ƙarfin ƙarfin injina yana ƙaruwa.

Bugu da ƙari, sinadaran da ke cikin bututun API 5L masu walda da marasa sulfur tare da irin wannan ƙarfin ƙarfe yana da bambanci, inda bututun da aka walda ke da buƙatu mafi girma da ƙarancin sinadarin carbon da sulfur.

Sinadaran da aka yi amfani da su wajen hada bututun PSL 1 tare da t ≤ 0.984” | |||||||

| Karfe Grade | Kashi na taro, % bisa ga nazarin zafi da samfura a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| matsakaicin b | matsakaicin b | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | |

| Bututu mara sumul | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Bututun da aka haɗa | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; kuma Mo ≤ 0.15%, | |||||||

| b. Ga kowace raguwar kashi 0.01% ƙasa da matsakaicin yawan carbon da aka ƙayyade, an yarda da ƙaruwar kashi 0.05% sama da matsakaicin yawan Mn da aka ƙayyade, har zuwa matsakaicin kashi 1.65% ga maki ≥ L245 ko B, amma ≤ L360 ko X52; har zuwa matsakaicin kashi 1.75% ga maki > L360 ko X52, amma < L485 ko X70; kuma har zuwa matsakaicin kashi 2.00% ga maki L485 ko X70., | |||||||

| c. Sai dai idan an amince akasin haka NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Sai dai idan an amince akasin haka., | |||||||

| f. Sai dai idan an amince akasin haka, NB + V = Ti ≤ 0.15%, | |||||||

| g. Ba a yarda da ƙara B da gangan ba, kuma ragowar B ≤ 0.001% | |||||||

| Sinadaran da aka yi amfani da su wajen hada bututun PSL 2 tare da t ≤ 0.984” | |||||||||||||||||||||

| Karfe Grade | Kashi na taro,% bisa ga nazarin zafi da samfura | Kayan Aikin Carbon | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Wani | CE IIW | CE PCM | |||||||||||

| matsakaicin b | matsakaicin | matsakaicin b | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | ||||||||||||

| Bututu mara sumul da welded | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Kamar yadda aka amince | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | ni,j | Kamar yadda aka amince | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Kamar yadda aka amince | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Kamar yadda aka amince | |||||||||||

| Bututun da aka haɗa | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | ni,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ni,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ni,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, iyakokin CE za su kasance kamar yadda aka amince. Iyakokin CEIIW da aka yi amfani da su fi C > 0.12% kuma iyakokin CEPcm za su yi aiki idan C ≤ 0.12%, | |||||||||||||||||||||

| b. Ga kowace raguwar kashi 0.01% ƙasa da matsakaicin da aka ƙayyade na C, an yarda da ƙaruwar kashi 0.05% sama da matsakaicin da aka ƙayyade na Mn, har zuwa matsakaicin kashi 1.65% ga maki ≥ L245 ko B, amma ≤ L360 ko X52; har zuwa matsakaicin kashi 1.75% ga maki > L360 ko X52, amma < L485 ko X70; har zuwa matsakaicin kashi 2.00% ga maki ≥ L485 ko X70, amma ≤ L555 ko X80; kuma har zuwa matsakaicin kashi 2.20% ga maki > L555 ko X80., | |||||||||||||||||||||

| c. Sai dai idan an amince akasin haka Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Sai dai in an yarda da haka, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% da Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Sai dai idan an amince akasin haka, | |||||||||||||||||||||

| g. Sai dai idan an amince akasin haka, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Sai dai in an yarda da haka, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% da MO ≤ 0.50%, | |||||||||||||||||||||

| i. Sai dai in an yarda da haka, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% da MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Sai dai in an yarda da haka, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% da MO ≤ 0.80%, | |||||||||||||||||||||

| l. Ga duk makin bututun PSL 2 banda makin da ke ɗauke da ƙananan bayanai j, waɗannan sun shafi. Sai dai idan an amince akasin haka, ba a yarda da ƙara B da gangan ba da kuma ragowar B ≤ 0.001%. | |||||||||||||||||||||

| PSL | Yanayin Isarwa | Bututun matakin |

| PSL1 | An daidaita shi, an daidaita shi, an daidaita shi daidai | A |

| An yi birgima kamar yadda aka yi birgima, an yi birgima kamar yadda aka yi birgima, an yi birgima kamar yadda aka yi amfani da thermomechanical, an yi amfani da thermomechanical, an yi daidai da yadda aka yi amfani da shi, an yi daidai da yadda aka yi amfani da shi, an yi daidai da kuma an yi shi daidai da yadda aka yi amfani da shi, ko kuma idan an yarda da Q&T SMLS kawai. | B | |

| An yi birgima kamar yadda aka yi birgima, an yi birgima kamar yadda aka yi birgima, an yi birgima kamar yadda aka yi amfani da thermomechanical, an yi amfani da thermomechanical, an yi daidai da tsari, an yi daidai da tsari, an yi daidai da tsari, an yi daidai da tsari, an yi daidai da tsari | X42, X46, X52, X56, X60, X65, da X70 | |

| PSL 2 | An birgima kamar yadda aka yi birgima | BR, X42R |

| Daidaita birgima, daidaita tsari, daidaita ko daidaita tsari da kuma daidaita shi | BN, X42N, X46N, X52N, X56N, X60N | |

| An kashe kuma an rage zafi | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| An samar da thermomechanical ko thermomechanical na thermomechanical | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Na'urar thermomechanical | X90M, X100M, X120M | |

| Isasshen (R, N, Q ko M) don matakan PSL2, yana cikin matakin ƙarfe |

PSL a takaice dai tana nufin matakin ƙayyade samfur kuma ta ƙunshi PSL1 da PSL2. Yana kama da matakin inganci.

PSL1 da PSL2 ba wai kawai sun bambanta a cikin gwaji ba, har ma da abubuwan da ke cikin sinadarai da halayen injiniya.

PSL2 ya fi PSL1 tsauri dangane da sinadaran da ke cikinsa, halayen taurin kai, gwajin tasiri, gwajin da ba ya lalatawa, da sauransu.

Gwajin Tasiri

Gwajin tasiri - Ba a buƙatar PSL1 ba, amma yana buƙatar PSL2 (banda X80).

Gwaji mara lalatawa

PSL1 ba ya buƙatar gwajin da ba ya lalatawa amma PSL2 yana buƙatar.

(Gwaji mara lalatawa: Gwaji da gwaji marasa lalatawa a cikin ma'aunin API 5L suna amfani da na'urar daukar hoto, ultrasonic, ko wasu hanyoyi (ba tare da lalata kayan ba) don gano lahani da lahani a cikin bututun mai.)

Marufi shinegabaɗaya tsirara, ɗaure waya ta ƙarfe, sosaiƙarfi.

Idan kuna da buƙatu na musamman, zaku iya amfani damarufi mai hana tsatsa, kuma mafi kyau.

Gargaɗi game da marufi da jigilar bututun ƙarfe na carbon

1.API 5L Karfe Bututudole ne a kare shi daga lalacewa da katsalandan, fitar da kaya da yankewa ke haifarwa yayin jigilar kaya, ajiya da amfani.

2. Lokacin amfani da bututun ƙarfe na carbon, ya kamata ku bi hanyoyin tsaro da suka dace kuma ku kula da hana fashewa, gobara, guba da sauran haɗurra.

3. A lokacin amfani,bututun ƙarfe na API 5Lya kamata a guji hulɗa da yanayin zafi mai yawa, kafofin watsa labarai masu lalata, da sauransu. Idan ana amfani da su a waɗannan muhallin, ya kamata a zaɓi bututun ƙarfe na carbon da aka yi da kayan aiki na musamman kamar juriyar zafi mai yawa da juriyar tsatsa.

4. Lokacin zabar bututun ƙarfe na carbon, ya kamata a zaɓi bututun ƙarfe na carbon na kayan da suka dace da ƙayyadaddun bayanai bisa la'akari da cikakkun bayanai kamar yanayin amfani, matsakaicin halaye, matsin lamba, zafin jiki da sauran abubuwa.

5. Kafin a yi amfani da bututun ƙarfe na carbon, ya kamata a yi bincike da gwaje-gwaje da suka wajaba domin tabbatar da ingancinsu ya cika buƙatun.

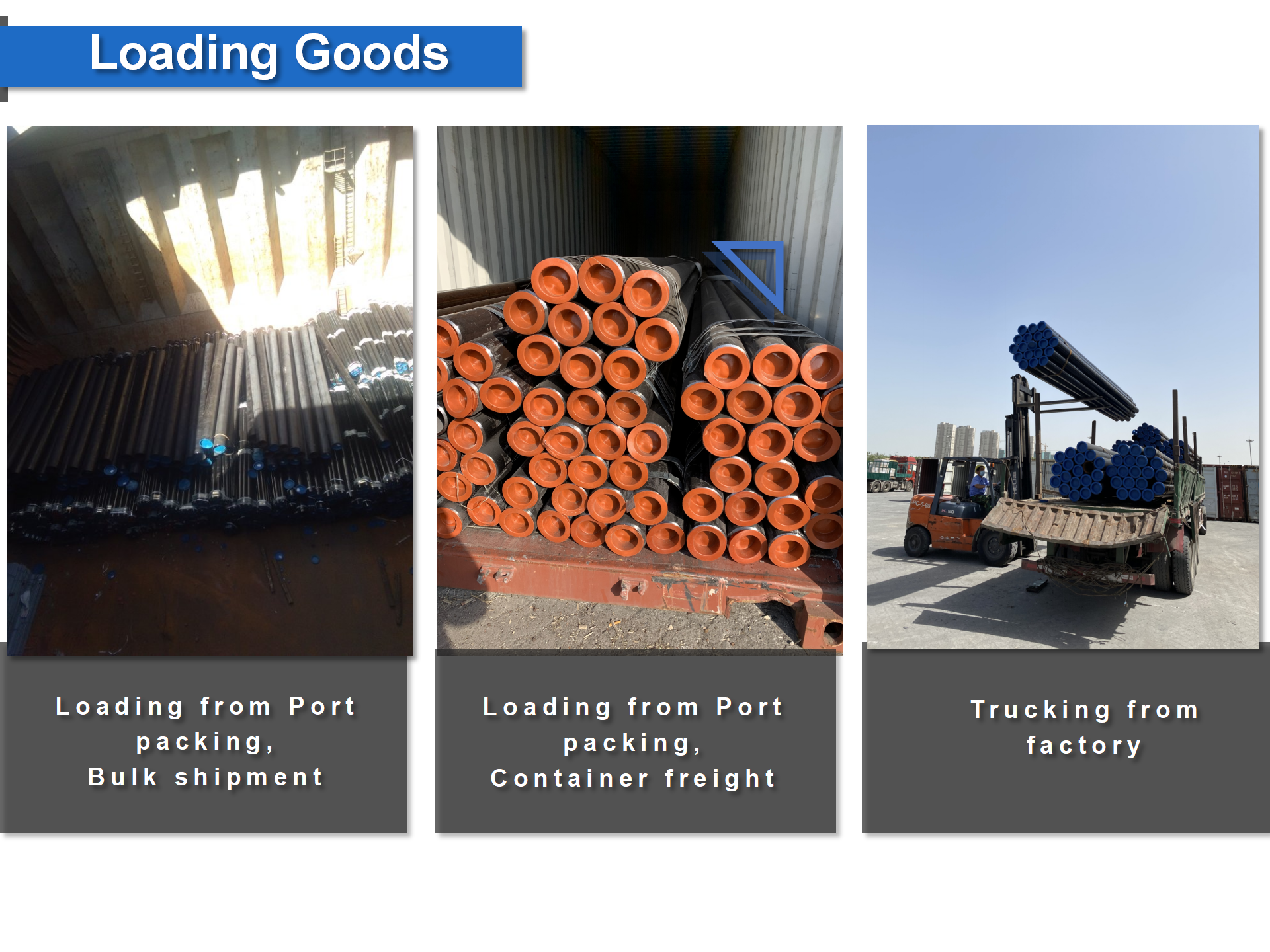

Sufuri:Jirgin Sama (Samfurin Isarwa), Jirgin Sama, Jirgin Kasa, Jirgin Ruwa (FCL ko LCL ko Girma)

T: Shin masana'anta ne?

A: Ee, mu masana'antar bututun ƙarfe ne mai karkace da ke cikin ƙauyen Daqiuzhuang, birnin Tianjin, China

T: Zan iya samun odar gwaji kawai tan da yawa?

A: Tabbas. Za mu iya jigilar kayan a gare ku tare da sabis na LCL. (Ƙarancin nauyin kwantena)

T: Idan samfurin kyauta ne?

A: Samfura kyauta ne, amma mai siye yana biyan kuɗin jigilar kaya.

T: Shin kai mai samar da zinare ne kuma kana da tabbacin ciniki?

A: Muna da shekaru 13 muna samar da zinare kuma muna karɓar tabbacin ciniki.