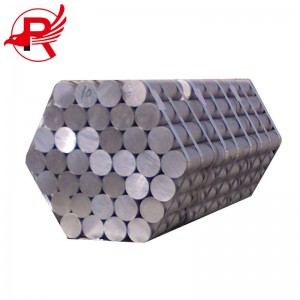

Farashin Sandar Zagaye ta Aluminum ta 6061

| Sunan Samfuri | ASTM B211, ASTM B221, ASTM B531 da sauransu | |

| Kayan Aiki | Aluminum, ƙarfe mai ƙarfe Jerin 2000: 2014A, 2014, 2017, 2024, 2219, 2017, 2017A, 2218 Jerin 5000: 5052, 5056, 5154, 5015, 5082, 5754, 5456, 5086, 5182 Jerin 6000: 6061, 6060, 6063, 6070, 6181, 6082 Jerin 7000: 7005, 7020, 7022, 7050, 7075 Jerin 8000: 8011, 8090 | |

| Sarrafawa | Fitarwa | |

| Siffa | Zagaye, Muƙamuƙi, Hex, da sauransu. | |

| Girman | Diamita (mm) | Tsawon (mm) |

| 5mm-50mm | 1000mm-6000mm | |

| 50mm-650mm | 500mm-6000mm | |

| shiryawa | Fitar da kayayyaki na yau da kullun Jakar filastik ko takarda mai hana ruwa shiga Akwatin katako (babu shaƙatawa na musamman) Faletin | |

| Kadara | Aluminum yana da takamaiman siffa ta zahiri ta sinadarai, ba wai kawai yana da nauyi mai sauƙi ba, laushi mai ƙarfi, amma yana da kyakkyawan ductility, wutar lantarki, wutar lantarki mai jure zafi, juriyar zafi da radiation. | |

Kauri shineSandunan aluminum 3003An samar da shi ba tare da kwangilar ba. Tsarin kamfaninmu mai kauri haƙuri yana cikin ±0.01mm. Bakin bututun yanke Laser, bututun yana da santsi kuma mai tsabta. Ana iya yanke shi na musamman zuwa kowane faɗi daga 20mm zuwa 1500mm. Gidan ajiya na 50,000. Yana samar da kayayyaki sama da tan 5,000 a rana. Don haka za mu iya samar musu da lokacin jigilar kaya da farashi mai sauri.

Sandunan aluminum 6061ba shi da guba kuma ana iya amfani da shi a cikin kayan shirya abinci. Yanayin haske na aluminum ya dace da kayan haske, ba ya ƙonewa don haka baya ƙonewa. Wasu amfani sun haɗa da sufuri, marufi na abinci, kayan daki, aikace-aikacen lantarki, gini, gini, injina da kayan aiki.

Ana iya amfani da sandunan aluminum don amfani da dama, ciki har da:

- Taron likita

- Gina jiragen sama

- Abubuwan da ke cikin tsarin

- Sufurin kasuwanci

- Kayan Wutar Lantarki

Lura:

1. Samfur kyauta, tabbacin inganci 100% bayan tallace-tallace, Goyi bayan kowace hanyar biyan kuɗi;

2. Duk wasu bayanai game da bututun ƙarfe mai zagaye suna samuwa bisa ga buƙatarku (OEM&ODM)! Farashin masana'anta za ku samu daga ROYAL GROUP.

Tsarin samarwa

Tsarin samar da karfen martensitic kamar haka: birgima mai zafimirgina- annealing - nutsewa cikin alkali - kurkura - tsinken tsinkewa - shafi - zane na waya - ƙawata - duba samfurin da aka gama - marufi

Tsarin samar da waya ta bakin ƙarfe ta Austenitic: na'urar birgima mai zafi - maganin mafita - nutsar da alkali - kurkura - tsinken itace - shafi - zane waya - ƙawata - tsaka tsaki - duba samfurin da aka gama - marufi

samfurinIduba

sandar ƙarfe ta aluminumkayan masana'antu ne da aka saba amfani da su kuma ana amfani da su sosai. Domin tabbatar da ingancin kayayyakin aluminum, ya zama dole a gwada ingancin sandunan aluminum. A ƙasa za mu gabatar da ƙa'idodin duba inganci na sandunan aluminum.

1. Bukatun kamanni: Sandar aluminum bai kamata ta kasance da tsagewa, kumfa, abubuwan da suka haɗa da su, lahani da sauran lahani ba. Ya kamata saman ya kasance lebur, tare da kyakkyawan ƙarewa kuma babu wani ƙyallen da za a iya gani.

2. Bukatun girma: diamita, tsayi, lanƙwasa da sauran girma na sandar aluminum ya kamata su cika ƙa'idar. Juriyar diamita da tsawon juriya bai kamata su wuce ƙa'idodin ƙasa ba.

3. Bukatun sinadaran da ake buƙata: Ya kamata sinadaran da ake buƙata na sandar aluminum su cika ƙa'idodin da jihar ta tanada, kuma daidaitattun sinadaran da ake buƙata ya kamata su kasance daidai da sinadaran da ake buƙata na takardar shaidar duba ingancin sandar aluminum.

1. Hanyar gano kamanni: Sanya sandar aluminum a ƙarƙashin tushen haske kuma ka lura ko akwai lahani da ƙaiƙayi a saman.

2. sandar zagaye ta aluminum: Ana amfani da na'urar auna diamita da na'urar auna tsawon don auna sandar aluminum. Ya kamata a yi auna lanƙwasa ta amfani da kayan gwaji na musamman.

3. Hanyar gano sinadaran da ke cikin sinadarai: Ana amfani da hanyar nazarin sinadarai don gano sandar aluminum.

Marufi gabaɗaya tsirara yake, ɗaure waya ta ƙarfe, yana da ƙarfi sosai.

Idan kuna da buƙatu na musamman, zaku iya amfani da marufi mai hana tsatsa, kuma mafi kyau.

Sufuri:Isarwa ta Gaggawa (Samfurin Isarwa), Jirgin Sama, Jirgin Kasa, Jirgin Ruwa (FCL ko LCL ko Babban Jiki)

Abokin Cinikinmu

T: Shin masana'anta ne?

A: Eh, mu masana'anta ne. Muna da masana'antarmu da ke birnin Tianjin, China. Bugu da ƙari, muna haɗin gwiwa da kamfanoni da yawa mallakar gwamnati, kamar BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, da sauransu.

T: Zan iya samun odar gwaji kawai tan da yawa?

A: Tabbas. Za mu iya jigilar kayan a gare ku tare da sabis na LCL. (Ƙarancin nauyin kwantena)

T: Idan samfurin kyauta ne?

A: Samfura kyauta ne, amma mai siye yana biyan kuɗin jigilar kaya.

T: Shin kai mai samar da zinare ne kuma kana da tabbacin ciniki?

A: Muna da shekaru bakwai na mai samar da zinare kuma muna karɓar tabbacin ciniki.