Na'urar Aluminum Alloy Coil 6061 Don Gina Gine-gine Da Aka Yi Amfani da Shi

| 1) 1000 Series Alloy (Gabaɗaya ana kiransa da aluminum mai tsabta na kasuwanci, Al> 99.0%) | |

| Tsarkaka | 1050 1050A 1060 1070 1100 |

| Mai halin ɗaci | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/ H26/H36 H18/H28/H38 H114/H194, da sauransu. |

| Ƙayyadewa | Kauri ≤30mm; Faɗi ≤2600mm; Tsawon ≤16000mm KO Nauyin (C) |

| Aikace-aikace | Kaya na Murfi, Na'urar Masana'antu, Ajiya, Duk nau'ikan Kwantena, da sauransu. |

| Fasali | Murfi Babban ƙarfin lantarki, aiki mai kyau mai jure tsatsa, zafi mai ɓoyewa mai yawa na narkewa, mai nuna haske sosai, kayan walda masu kyau, ƙarancin ƙarfi, kuma ba ya dace da maganin zafi. |

| 2) Jerin Alloy na 3000 (Gabaɗaya ana kiransa Al-Mn Alloy, ana amfani da Mn azaman babban sinadarin ƙarfe) | |

| Alloy | 3003 3004 3005 3102 3105 |

| Mai halin ɗaci | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/ H36 H18/H28/H38 H114/H194, da sauransu. |

| Ƙayyadewa | Kauri ≤30mm; Faɗi ≤2200mm Tsawon ≤12000mm KO Nauyin (C) |

| Aikace-aikace | Kayan ado, na'urar nutsar da zafi, bangon waje, ajiya, zanen gado don gini, da sauransu. |

| Fasali | Kyakkyawan juriya ga tsatsa, bai dace da maganin zafi ba, mai juriya ga tsatsa aiki, kadarar walda mai kyau, kyakkyawan filastik, ƙarancin ƙarfi amma ya dace don ƙarfafa aikin sanyi |

| 3) Jerin Alloy 5000 (Gabaɗaya ana kiransa Al-Mg Alloy, ana amfani da Mg azaman babban sinadarin ƙarfe) | |

| Alloy | 5005 5052 5083 5086 5182 5754 5154 5454 5A05 5A06 |

| Mai halin ɗaci | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, da sauransu. |

| Ƙayyadewa | Kauri ≤170mm; Faɗi ≤2200mm; Tsawon ≤12000mm |

| Aikace-aikace | Farantin Ruwa, Zoben da aka Ja, Hannun Jarin Zobe, Mota Takardun Jiki, Allon Ciki na Mota, Murfin Kariya a Injin. |

| Fasali | Duk fa'idodin ƙarfe na aluminum na yau da kullun, ƙarfin juriya mai ƙarfi & ƙarfin yawan amfanin ƙasa, kyakkyawan aiki mai jure lalata, dukiyar walda mai kyau, ƙarfin gajiya mai kyau, kuma ya dace da anodic oxidation. |

| 4) Jerin Alloy 6000 (wanda aka fi sani da Al-Mg-Si Alloy, ana amfani da Mg da Si a matsayin manyan abubuwan haɗin gwal) | |

| Alloy | 6061 6063 6082 |

| Mai halin ɗaci | OF, da sauransu. |

| Ƙayyadewa | Kauri ≤170mm; Faɗi ≤2200mm; Tsawon ≤12000mm |

| Aikace-aikace | Motoci, Aluminum Don Jiragen Sama, Masana'antu Mould, Kayan Inji, Jirgin Ruwa, Kayan Aikin Semiconductor, da sauransu |

| Fasali | Kyakkyawan aiki mai jure lalata, kayan walda masu kyau, kyakkyawan iskar oxygen, mai sauƙin fesawa, launi mai kyau na iskar shaka, da kuma ingantaccen injin aiki. |

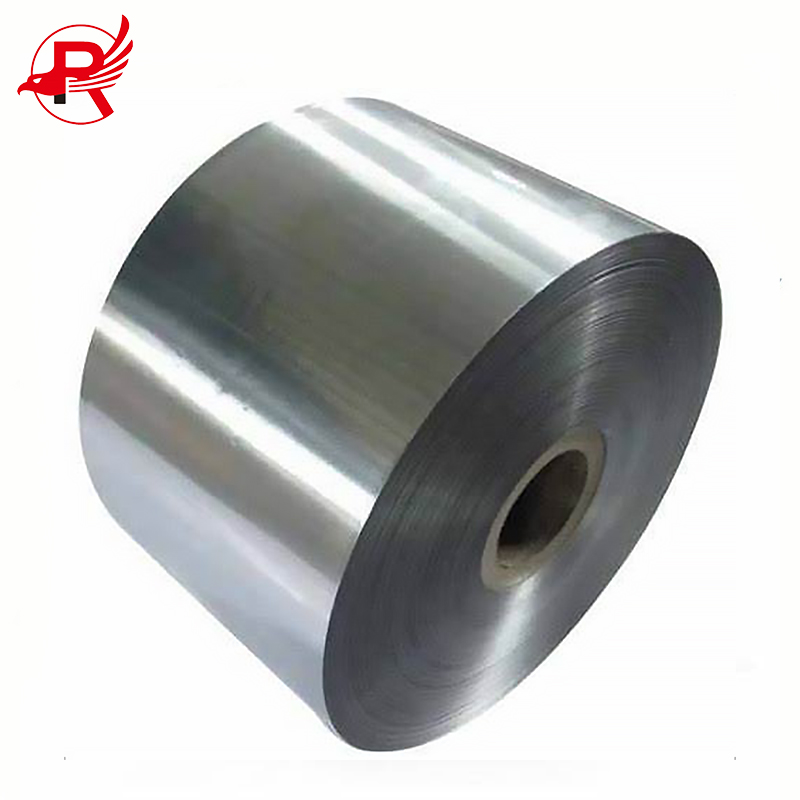

A matsayin kayan aiki mai yawa, na'urorin aluminum suna da amfani iri-iri a fannoni daban-daban.

Da farko dai, a fannin gini, ana amfani da na'urorin aluminum wajen yin ado a bango na waje, rufin gida, rufi, firam ɗin taga, da sauransu. Saboda na'urorin aluminum suna da kyawawan juriya ga yanayi da kuma kayan ado, suna iya biyan buƙatun kamanni da dorewa na gine-gine.

Abu na biyu, a fannin sufuri, ana amfani da na'urorin aluminum wajen kera harsashi, bangarorin jiki, sassan ciki, da sauransu na ababen hawa kamar motoci, jiragen ƙasa, da jiragen sama. Yanayin na'urorin aluminum masu sauƙi yana taimakawa wajen rage nauyin motar gaba ɗaya da kuma inganta ingancin mai.

Bugu da ƙari, a fannin kayan lantarki da na lantarki, ana amfani da na'urorin aluminum wajen kera akwatunan batir, na'urorin radiators, akwatunan kayayyakin lantarki, da sauransu. Ƙarfin wutar lantarki da kuma yadda zafin na'urorin aluminum ke watsawa sun sanya shi muhimmin abu a masana'antar lantarki da lantarki.

Bugu da ƙari, a fannin marufi, ana amfani da marufi na aluminum sosai a cikin marufi na abinci, marufi na magunguna, da sauransu. Saboda marufi na aluminum suna da kyakkyawan hatimi da juriya ga iskar shaka, suna iya kare inganci da amincin kayayyakin da aka marufi yadda ya kamata.

Gabaɗaya, na'urorin aluminum suna da amfani mai mahimmanci a cikin gini, sufuri, kayan lantarki, marufi da sauran fannoni. Nauyinsa mai sauƙi, juriya ga tsatsa, da sauƙin sarrafawa sun sa ya zama ɗaya daga cikin kayan da ba makawa a masana'antu daban-daban.

| FAƊI(MM) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1000 | 1 | 2 | 3 | 4 | Wani |

| 1219 | 1 | 2 | 3 | 4 | Wani |

| 1220 | 1 | 2 | 3 | 4 | Wani |

| 1500 | 1 | 2 | 3 | 4 | Wani |

| 2000 | 1 | 2 | 3 | 4 | Wani |

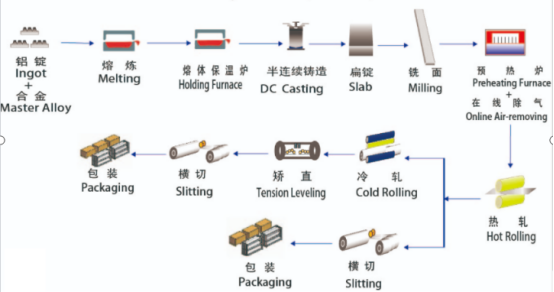

Samar daƙarfe na aluminumYawanci yakan ɗauki matakai da yawa. Da farko, farawa daga ingots na aluminum, ta hanyar narkewa da kuma simintin da ba shi da ci gaba, ana samun aluminum mai ruwa wanda ya cika buƙatun. Na gaba, ana jefa aluminum mai narkewa cikin farantin aluminum ta hanyar siminti da birgima akai-akai, sannan a rage kauri a hankali ta hanyar injin birgima akai-akai don samar da murfin aluminum da ake buƙata. Daga baya, ana kashe murfin aluminum kuma ana rufe shi don daidaita tsarinsa da halayensa da kuma inganta ƙarfinsa da ƙarfinsa. A ƙarshe, ana iya shafa murfin aluminum don ƙara juriya ga tsatsa ko kayan ado a saman su. Duk tsarin samarwa yana buƙatar kulawa mai ƙarfi don tabbatar da cewa ingancin samfur da aikinsu sun cika buƙatun da aka saba. A lokaci guda, kare muhalli, amfani da makamashi da sauran fannoni suma batutuwa ne da ake buƙatar mayar da hankali a kansu yayin aikin samarwa.

Ga wasu muhimman abubuwan da za a yi la'akari da su yayin dubana'urar aluminum:

1. Girman: Duba girmanna'urar ƙarfe ta aluminuma kan ƙayyadadden bayanin da masana'anta suka bayar. Tabbatar cewa sun yi daidai da kauri, faɗi da tsawon.

2. Ingancin saman: Duba saman na'urar don ganin ko akwai ƙage, ko wasu lahani. Ya kamata saman ya kasance santsi ba tare da wata illa da za a iya gani ba.

3. Daidaiton launi: launin na'urar ya kamata ya kasance daidai a cikin na'urar. Duk wani canji a launi na iya nuna matsala a tsarin samarwa.

4. Kauri na shafa: Idan na'urar tana da shafa, ya kamata a duba kauri na shafa don tabbatar da cewa ta cika ƙa'idodin da aka ƙayyade. Rufin da ya yi siriri ko kauri sosai na iya shafar dorewa da aikin samfurin.

5. Sinadarin sinadarai: a yi nazarin sinadaran aluminum don tabbatar da cewa ya cika ƙa'idodin da ake buƙata. Wannan ya haɗa da duba ko akwai ƙazanta ko wasu abubuwan da za su iya shafar ingancin samfur.

6. Marufi da Lakabi: Tabbatar cewa an naɗe naɗaɗɗen naɗaɗɗen kuma an yi musu laƙabi da kyau don jigilar kaya da ajiya. Ya kamata marufi ya kasance mai ƙarfi kuma an ƙera shi don kare naɗaɗɗen yayin jigilar kaya.

7. Tsarin Kera Kayayyaki: Ana duba tsarin kera kayan aiki don tabbatar da cewa ya cika ƙa'idodin da ake buƙata kuma an kula da dukkan kayan aiki yadda ya kamata kuma suna aiki yadda ya kamata.

Tsarin dubawa mai inganci zai taimaka wajen gano duk wata matsala da ka iya tasowa game da samfurin da kuma tabbatar da cewa ya cika ƙa'idodin ingancin da ake buƙata.

Marufi gabaɗaya tsirara yake, ɗaure waya ta ƙarfe, yana da ƙarfi sosai.

Idan kuna da buƙatu na musamman, zaku iya amfani da marufi mai hana tsatsa, kuma mafi kyau.

Sufuri:Isarwa ta Gaggawa (Samfurin Isarwa), Jirgin Sama, Jirgin Kasa, Jirgin Ruwa (FCL ko LCL ko Babban Jiki)

T: Shin masana'anta ne?

A: Eh, mu masana'anta ne. Muna da masana'antarmu da ke birnin Tianjin, China. Bugu da ƙari, muna haɗin gwiwa da kamfanoni da yawa mallakar gwamnati, kamar BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, da sauransu.

T: Zan iya samun odar gwaji kawai tan da yawa?

A: Tabbas. Za mu iya jigilar kayan a gare ku tare da sabis na LCL. (Ƙarancin nauyin kwantena)

T: Idan samfurin kyauta ne?

A: Samfura kyauta ne, amma mai siye yana biyan kuɗin jigilar kaya.

T: Shin kai mai samar da zinare ne kuma kana da tabbacin ciniki?

A: Muna da shekaru bakwai na mai samar da zinare kuma muna karɓar tabbacin ciniki.